What’s New

NEW AQUABlack® warm mix foaming gun

Maxam Equipment introduces a new style of foaming gun for its world-reknown AQUABlack warm mix asphalt system. The new foaming gun is a direct replacement for original foaming guns and includes these features:

- All wetted parts are stainless steel components to prevent rust and scale formation

- All parts required to change to new style are included

- External stainless steel cartridges allow for easy maintenance access

- Available in either electric or hot oil heat

- Fits standard 3″ line, adaptable to all existing systems.

Please send a photo of your existing foaming head so we can determine the exact model of your unit.

Introducing Maxam California Bulk Sampler

Maxam’s California Bulk Sampler was developed in direct response to Caltran’s requirement to take bulk samples from the plant.

The air operated clam gates are easily chattered to fill a Caltran approved Gilson Quartermaster sample splitter, and the onboard air tank contains enough air to open and close the gats several times.

After empting, the hopper is lowered by battery operated electric winch, and locks easily for transport with cam lock latches.

When at the plant site, the hopper is quickly powered to the upright loading position, where it automatically locks into place. Once loaded the trailer mounted hopper is ready for transport to the lab site.

Introducing Maxam SAFE-SAMPLER

Finally … A safe method to sample liquid asphalt.

Totally enclosed sampling system provides means to safely dispense liquid asphalt into quart or gallon containers without the danger associated with open sampling.

Totally enclosed sampling system provides means to safely dispense liquid asphalt into quart or gallon containers without the danger associated with open sampling.

Access door interlock keeps valve safely closed while personnel place and remove sampling containers.

Handling liquid asphalt poses a threat of serious injury. Eliminate that present danger with the Maxam SAFE-SAMPLER:

- Heated spool for easy installation into any standard 3” or 4” asphalt line

- Heated valve and spout for free flow of liquid without plugging

- Full view high temperature glass allows observation of sampling

- Lightweight aluminum construction

- Sampling control valve cannot be opened if safety door is not closed

Download the SAFE-SAMPLER PDF for printed information.

Introducing Accu Flo™ Additive Meter System

MAXAM’s Accu Flo™ System is the only system available capable of adding viscous additives accurately without heating the additive tank.

Features:

- Positive displacement, variable speed pump

- Coriolis mass flow meter for accuracy

- High efficiency demand-style inline heater

- On-board controls

Visit the Accu Flo™ Additive Meter System page for a video demonstration and more information.

Introducing Flo-Blaster™ Raptor Recycle System

Flo-Blaster™ technology eliminates plugging and bridging when conveying RAP or RAS. Numerous air cannons, strategically positioned on all sides of the bin, maintain a consistent flow of material. Each cannon fires in rapid succession breaking up any slugs, plugs or bridging to ensure a consistent flow.

Flo-Blaster™ technology eliminates plugging and bridging when conveying RAP or RAS. Numerous air cannons, strategically positioned on all sides of the bin, maintain a consistent flow of material. Each cannon fires in rapid succession breaking up any slugs, plugs or bridging to ensure a consistent flow.

- Prevents plugging, bridging and inconsistent flow of RAP and RAS

- Numerous air cannons positioned strategically on all sides of the bin

- Fires shotgun blasts of high pressure air in rapid succession

- Fires automatically when “no-flow” switch is activated

- Can be retrofitted on any bin and is standard on all Maxam Raptor® recycle bins

Visit the Flo-Blaster™ Raptor Recycle System page for a video demonstration and more information.

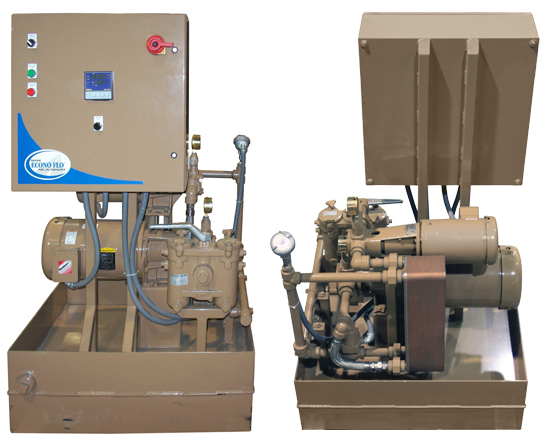

Introducing Econo Flo™ Fuel Oil Preheater

Get the most efficient fuel burn possible with the Maxam Econo Flo™ fuel oil pre-heater. Precise control of fuel temperature delivers the correct viscosity for optimum atomization and a complete burn.

Get the most efficient fuel burn possible with the Maxam Econo Flo™ fuel oil pre-heater. Precise control of fuel temperature delivers the correct viscosity for optimum atomization and a complete burn.

Features:

- Positive displacement variable speed pump

- PID controller

- Patented flat plate heat exchanger

- Compact design – small footprint

- Excess fuel is redirected back to heat exchanger,not to the tank, reducing heating cost

Visit the Econo Flo™ Fuel Oil Preheater page for a video demonstration and more information.

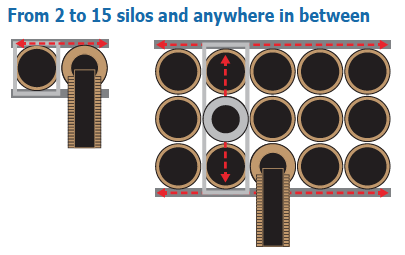

Introducing Perma Stor™ Silo System

The simple and reliable design saves you time and money. The Transporter™ Bintop Conveying System rides on rails, eliminating troubles associated with conveyors; and the Oxi-Free™ oxygen purge system provides an eco-friendly way to remove oxygen and seal the silo for effective overnight storage.

The simple and reliable design saves you time and money. The Transporter™ Bintop Conveying System rides on rails, eliminating troubles associated with conveyors; and the Oxi-Free™ oxygen purge system provides an eco-friendly way to remove oxygen and seal the silo for effective overnight storage.

- Long term storage without oxidation

- Lower maintenance cost

- Lower initial cost

- Increase operating income

- Retrofittable on any system

Visit the Perma Stor Silo System page for a video demonstration and more information.

Maxam Announces Partnership with FAYAT Road Building Equipment to Globally Expand AQUABlack® Warm Mix System

July 31, 2011 – Kansas City, MO. Maxam has announced a partnership with FAYAT France to market Maxam’s AQUABlack® warm mix system throughout Europe, Asia and Africa.

FAYAT is one of France’s leading construction businesses. They manufacture and market asphalt plants throughout Europe, Asia and Africa through their wholly owned subsidiaries Ermont and Marini.

Maxam is eager to share this technology with asphalt producers across the world. “We are incredibly excited about this endeavor and look forward to a long and healthy relationship with FAYAT. With our advanced technology and their resources and contacts, we expect this relationship to benefit both companies greatly. Businesses in our industry across the world will benefit from our system,” Andy Welch, Project Manager of Maxam Equipment, Inc. stated.

For more information, please contact Maxam Equipment at (800) 292-6070 or visit our AQUABlack® Warm Mix Asphalt page.

Asphalt Unloading Pump Unit

Asphalt Unloading Pump Unit

- Rotan® Pump with relief valve and packing seal

- 15 HP TEFC 3PH/460V Motor

- Drive with guard

- Mounted on heavy duty steel skid base

- 200 GPM capacity

- Oversized oil heated single basket strainer

Maxam AutoLube™ Chain Saver

Maxam AutoLube™ Chain Saver

The AutoLube™ Chain Saver is designed specifically for the rugged environment of an asphalt plant. Fully automatic control ensures that chains and sprockets are always properly lubricated. And, since lubrication can be controlled precisely, there is no mess created by excess runoff.

The oversized reservoir holds two full quarts of lubricating oil, and the high strength clear plastic construction makes it easy to see when additional oil needs to be added.

The electronic timer allows adjustment of both on and off times from zero to 24 hours providing for proper lubrication without waste.

The system is enclosed in a weather proof enclosure and is easy to install. 120V power can come from any close source, and an interlock is provided so that the system is energized only when the equipment is running.

- Fully automatic timer control for both on-time and off-time

- Operates only when your equipment is running

- Can reduce chain wear as much as 300%

- Precise control eliminates over or under oiling

- No mess left behind because proper control eliminates runoff

- 2 feed lines provide lubrication to both ends of the chain roller

- Snap Lock flexible feed lines are easy to form and retain their position