Traditional trunnions are touchy and take experienced hands to align them. Adjustments are often a time consuming, trial and error process. Compounding the problem is the fact that adjustment is load sensitive – meaning you won’t be properly aligned when you change production rate. It’s a high stakes game when you consider the cost for replacing a damaged drum tire, trunnions or bearings.

Traditional trunnions are touchy and take experienced hands to align them. Adjustments are often a time consuming, trial and error process. Compounding the problem is the fact that adjustment is load sensitive – meaning you won’t be properly aligned when you change production rate. It’s a high stakes game when you consider the cost for replacing a damaged drum tire, trunnions or bearings.

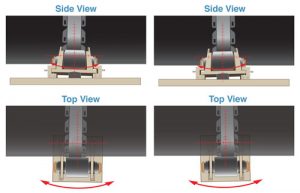

MAXAM’s TrooTrac™ Asphalt Drum Trunnions solve this problem by automatically and continuously aligning to accommodate load changes and/or imperfectly mounted drum tires.

Furthermore, TrooTrac™ Trunnions are never skewed, like all other manufacturer’s trunnions, to accommodate the downhill thrust load. Instead, MAXAM uses a separate TrooTrac™ Thrust Load System to handle all the thrust load. Thereby, MAXAM TrooTrac™ Trunnions constantly maintain full contact with the drum tire face. All others are, by design, not full contact because they have to be skewed.

The patented system is exclusive to MAXAM, but it is available to you on MAXAM equipment, or by MAXAM retrofit of your existing equipment.

TrooTrac™ Advantages:

- Extend life of tires

- Reduce maintenance

- Eliminate trial and error alignments

- Eliminate time spent aligning trunnions

- Eliminate risk of damage caused by misaligned trunnions

- Reduce wear on trunnion rollers

- Reduce wear on trunnion bearings

- Reduce pressure on thrust roller bearings

Also See SOLO™ Drum Mix Plant System